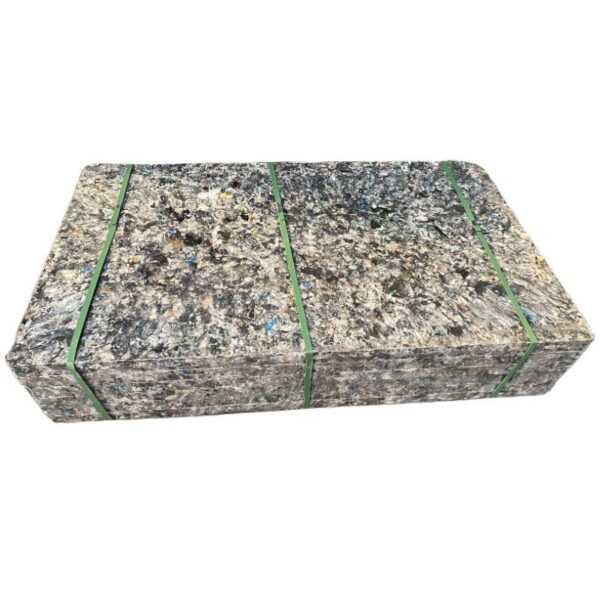

GMT brick pallet is also called GMT block pallet, composite brick pallet, plastic block pallet, fiber brick pallet, glass fiber brick pallet, block machine pallet, etc. it is kind of plastic fiber block pallet used for concrete block machine, because the brick pallet price is cheap, low cost and good quality, very strong and long lasting, its normal life can reach 8 years more, even 10 years. As GMT brick pallet factory, brick pallet is better than others, mainly based on two factors, using better raw materials and higher pressing machine of 3000 tons pressure, to make sure the GMT block pallet is pressed extremely solid enough, in order to bear a heavy load of blocks and the block machine vibration.

Key Characteristics of GMT Pallets for Concrete Block Machines

- Material Composition: GMT pallets are made from a combination of glass fibers and thermoplastic resins. The glass fibers impart strength and reinforcement to the pallet, while the thermoplastic resins act as a binding agent, ensuring durability and dimensional stability.

- High Strength and Load-Bearing Capacity: GMT pallets are engineered to withstand heavy loads without warping or cracking. Their high strength and load-bearing capacity make them ideal for supporting the weight of concrete blocks during the molding and curing stages.

- Weather and Moisture Resistance: GMT pallets are designed to be weather-resistant, making them suitable for use in various environmental conditions. Unlike traditional wooden pallets that can degrade when exposed to moisture, GMT pallets retain their structural integrity, even in humid or wet environments.

- Consistent Dimensions: One of the key advantages of GMT pallets is their consistent dimensions. This uniformity ensures that each concrete block produced maintains precise shape and size, resulting in a more professional and aesthetically pleasing end product.

- Chemical and Corrosion Resistance: GMT pallets exhibit excellent resistance to chemicals and corrosive substances commonly used in the concrete block manufacturing process. This resistance prolongs the pallet’s lifespan and reduces the need for frequent replacements.

- Low Maintenance: GMT pallets require minimal maintenance compared to traditional wooden pallets. They do not splinter, crack, or absorb moisture, eliminating the need for regular repairs and replacements, thereby reducing production downtime and costs.

- Eco-Friendly and Sustainable: The manufacturing process of GMT pallets involves the use of recycled materials, contributing to eco-friendly practices and promoting sustainability in the construction industry.

Advantages of GMT Pallets for Concrete Block Machines

- Enhanced Production Efficiency: The consistent dimensions and durability of GMT pallets enable smoother and faster production cycles. The concrete blocks can be molded and cured with precision, reducing the likelihood of product defects and wastage.

- Cost-Effectiveness: While GMT pallets may have a higher upfront cost compared to wooden pallets, their extended lifespan and reduced maintenance requirements lead to cost savings in the long run. Manufacturers can achieve a higher return on investment due to the pallets’ longevity and reusability.

- Improved Product Quality: GMT pallets ensure uniformity in the shape and size of concrete blocks, resulting in a more professional and marketable final product. The consistency in block dimensions also aids in tighter joint construction during building projects.

- Safety and Handling: GMT pallets offer a safer working environment for employees during the concrete block manufacturing process. Their smooth surfaces prevent splinters or nails from causing injuries, and their lightweight nature makes them easier to handle and transport.

- Environmental Benefits: By opting for GMT pallets made from recycled materials, concrete block manufacturers contribute to reducing their ecological footprint and promoting sustainable practices within the construction industry.

Conclusion

The popularity of GMT pallets for concrete block machines continues to grow, thanks to their outstanding characteristics and numerous advantages. With high strength, weather resistance, and consistent dimensions, these pallets enhance production efficiency, reduce costs, and improve the overall quality of concrete blocks. Moreover, their eco-friendly nature aligns with the increasing demand for sustainable building practices.

FAQs: GMT Pallets for Concrete Block Machines

- Can GMT pallets be customized to fit specific concrete block machine models?Yes, GMT pallets can be customized to match the dimensions and specifications required by different concrete block machine models. Manufacturers can request pallets that precisely align with their machinery for seamless integration.

- How do GMT pallets contribute to reducing environmental impact in the construction industry?GMT pallets are made from recycled materials, such as glass fibers and thermoplastic resins. By utilizing these sustainable resources, manufacturers help decrease the demand for virgin materials and reduce waste, making GMT pallets an eco-friendly choice.

- Are GMT pallets suitable for use in various weather conditions?Yes, GMT pallets are designed to withstand diverse weather conditions, including high temperatures, humidity, and rain. Their weather and moisture resistance ensure that they maintain their structural integrity, making them suitable for outdoor use.

- What maintenance practices are required for GMT pallets used in concrete block machines?GMT pallets require minimal maintenance. Regular cleaning and inspection for any signs of damage are sufficient to keep them in optimal condition. Unlike wooden pallets, GMT pallets do not need frequent repairs or replacements.

- Can GMT pallets be recycled at the end of their lifespan?Yes, GMT pallets are recyclable at the end of their useful life. The materials used in their manufacturing process can be reclaimed and used to produce new GMT pallets or other products, contributing to a closed-loop recycling system.

please feel free to contact us at whatsapp +86 1895499 3585 to give you a satisfactory buying experience.

Reviews

There are no reviews yet.