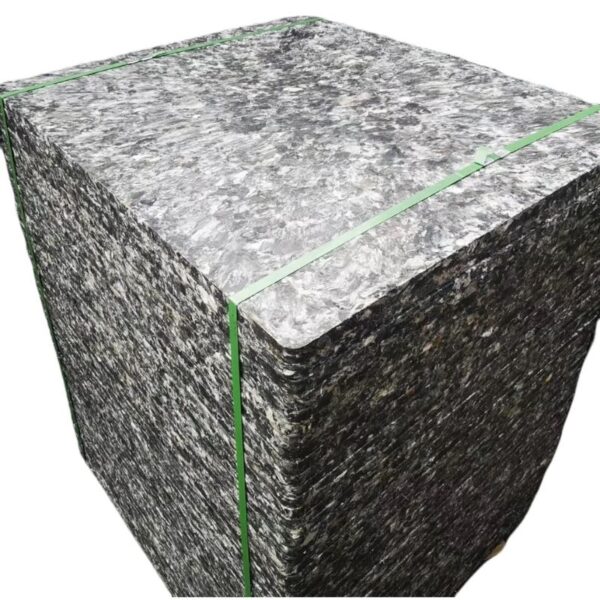

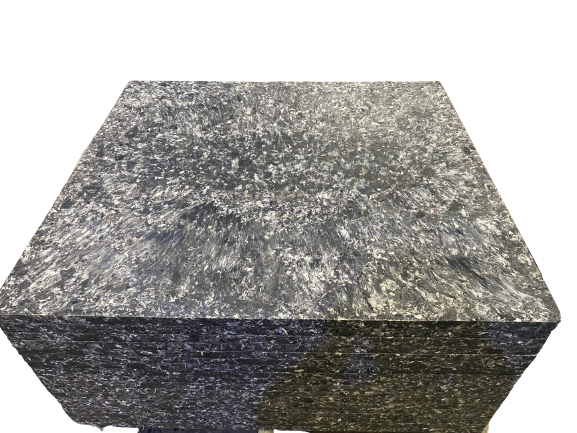

GMT Fiber brick pallet is made from the leftovers from car inner roofs, it container large quantity of plastic fiber, glass fiber, also big adhesive. The fiber brick pallet is made via crushing, tearing the car roof leftovers into small pieces, heating: heat the small pieces into hot melted status, adding some more PP particles as glue reinforcement, weighing certain weight for different size pallet, then put into the pallet mould of pressing machine, after big pressure pressing, the hot fiber brick pallet comes out, then the fiber pallet is put into cooling machine to cool down the fiber brick pallet, after around 5 minutes, the finished fiber brick pallets can be taken out from cooling machine.

High-Quality GMT Brick Pallets: Enhancing Efficiency in the Brick Industry

Introduction

In the world of brick manufacturing, ensuring the safe and efficient transportation of products is crucial. This is where GMT brick pallets come into play, offering a revolutionary solution to traditional wooden pallets. This article will explore the benefits of high-quality GMT brick pallets, their manufacturing process, applications, and why they have become an essential component in the brick industry.

Benefits of High-Quality GMT Brick Pallets

Enhanced Durability and Longevity

GMT brick pallets are engineered to withstand the demanding conditions of the brick manufacturing environment. Their high strength and rigidity ensure they can endure heavy loads and rough handling without succumbing to wear and tear. Unlike wooden pallets that can splinter or break, GMT pallets offer long-lasting performance, making them a cost-effective investment.

Increased Load-Bearing Capacity

High-quality GMT brick pallets boast impressive load-bearing capacities, allowing brick manufacturers to stack more products efficiently. The superior strength of GMT pallets ensures stability even under substantial loads, minimizing the risk of product damage during storage and transportation.

Resistance to Moisture and Weather Conditions

Traditional wooden pallets are susceptible to moisture absorption, leading to warping and degradation over time. GMT brick pallets, on the other hand, are moisture-resistant, ensuring dimensional stability and maintaining their structural integrity in various weather conditions, including rain and extreme temperatures.

GMT Brick Pallet Manufacturing Process

To produce high-quality GMT brick pallets, a combination of carefully selected raw materials and advanced molding techniques is employed.

Raw Materials Used in GMT Pallet Production

GMT pallets are primarily composed of glass fibers, which provide strength and reinforcement, and thermosetting resins, which bind the fibers together. These raw materials are sourced from recycled materials, making GMT pallets an eco-friendly choice.

GMT Pallet Molding Techniques

Two common molding techniques are used in the production of GMT brick pallets:

Compression Molding

Compression molding involves placing the raw materials into a mold cavity and applying heat and pressure. This process results in a sturdy and consistent pallet with high-quality surface finish.

Injection Molding

Injection molding entails injecting the molten GMT material into a mold, allowing for intricate designs and customizations. This method is ideal for producing pallets with specific dimensions and features.

Advantages of GMT Pallets over Traditional Wooden Pallets

Sustainability and Environmental Benefits

GMT brick pallets contribute to sustainable practices by utilizing recycled materials. This eco-friendly approach helps reduce the demand for virgin materials and minimizes waste, making GMT pallets a green alternative to traditional wooden pallets.

Cost-Effectiveness and Reduced Maintenance

Although GMT pallets may have a slightly higher initial cost, their extended lifespan and low maintenance requirements offset this investment. Unlike wooden pallets that need regular repair and replacement, GMT pallets remain durable and intact for longer periods, resulting in cost savings for brick manufacturers.

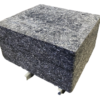

Consistency and Precision in Design

GMT pallets are manufactured using molds, ensuring precise and consistent dimensions with each pallet produced. This uniformity leads to improved production efficiency, as products can be stacked and transported with ease and accuracy.

GMT Brick Pallet Applications and Uses

GMT brick pallets find versatile applications across various industries:

Brick Manufacturing Industry

In the brick manufacturing process, GMT pallets play a critical role in providing a stable platform for molding and curing bricks. Their durability and resistance to high temperatures make them an excellent choice for this demanding application.

Transportation and Logistics

GMT brick pallets streamline the transportation of bricks from manufacturing facilities to construction sites. With their high load-bearing capacity and dimensional stability, these pallets ensure secure and efficient product delivery.

Warehouse Storage and Handling

Brick warehouses benefit from GMT pallets’ ability to withstand heavy loads, making them a reliable storage solution. The consistent dimensions of GMT pallets allow for organized and space-efficient stacking, optimizing warehouse operations.

Key Considerations for Selecting High-Quality GMT Brick Pallets

When choosing GMT brick pallets for your brick manufacturing business, consider the following factors:

Weight-Bearing Capacity

Assess the weight-bearing capacity of the pallets to ensure they can handle the specific brick types and quantities you produce.

Design and Dimensions

Opt for pallets with designs and dimensions that align with your brick manufacturing processes and storage requirements.

Customization Options

Explore manufacturers offering customization options, such as logo embossing or color variations, to create a unique brand identity.

How High-Quality GMT Pallets Improve Brick Manufacturing Efficiency

Reduced Product Damage and Breakages

GMT pallets’ robust design minimizes product breakages during handling and transportation, reducing material waste and improving overall production efficiency.

Faster Production Cycles

With GMT pallets’ ease of use and precise dimensions, brick manufacturers can expedite the production process, resulting in increased productivity and shorter lead times.

Streamlined Handling and Storage

GMT pallets’ uniform dimensions facilitate smooth material handling and organized storage, optimizing space utilization within warehouses.

Rhinos Pallets factory is looking for the wholsalers in the world, if you are interest in this new business industry,

please feel free to contact us at whatsapp +86 1895499 3585 to give you a satisfactory buying experience.

Reviews

There are no reviews yet.