Fiber Brick Pallet: new brick pallet widely accepted in the world by concrete block plant owners

Introduction

In the process of producing concrete blocks, brick pallets play a crucial role in safely transporting and storing bricks. With technological advancements, fiber brick pallets have emerged as a sustainable and efficient alternative to traditional pallets.

What is a Fiber Brick Pallet?

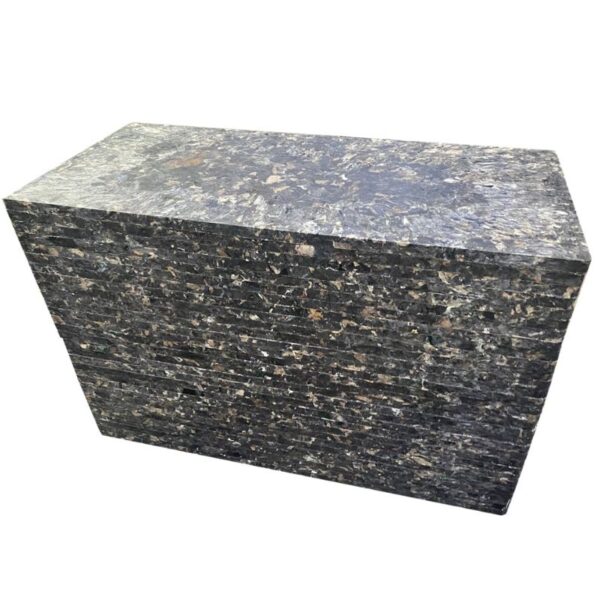

A fiber brick pallet is made of the leftovers from the raw materials making inner decoration materials like the interior ceiling, the PE (polythene) foot mat, the car seating suites, etc for automobile.

Unlike traditional pallets made of wood, bamboo or plastic, fiber brick pallets incorporate synthetic fibers, such as jute, hemp, fiberglass, or carbon fiber. The combination of these fibers with a composite material results in a lightweight yet robust pallet. These pallets offer various advantages over their traditional counterparts, such as enhanced durability, increased load-bearing capacity, and resistance to moisture and chemicals. By choosing fiber brick pallets, concrete block plants can experience improved efficiency and reduced environmental impact.

Understanding the Fiber Material

The choice of fiber material significantly impacts the performance of the brick pallet. Natural fibers like jute and hemp offer biodegradability and sustainability, making them attractive options for eco-conscious businesses. On the other hand, synthetic fibers like fiberglass and carbon fiber provide exceptional strength and resistance to extreme conditions. The fibers undergo a rigorous processing and reinforcement process to ensure they are tightly integrated into the composite material, enhancing the pallet’s overall integrity and longevity.

the Fiber Brick pallet forming process

The GMT brick pallet raw materials of car interior decoration materials are teared into small piece by shredding machine. Then these teared materials will be weighed by certain weight accurately for different size brick pallets, and add other certain strong glue materials into it. Next step, the weighed materials will be wrapped into a soft but thick plastic tarpaulin to be heated to high temperature under heating machine, after several minutes, the heated materials are taken out and put onto the customized size mould on the pressing machine, after it is being pressed for 5 minutes under 3000 tons pressure, it will be taken out, and remove some retails on the pallets, then put it on the cold pressing machine to make it cold and more flat, now the final GMT brick pallets come out.

Fiber brick pallet Technical Parameters

| Test Items | Test Result | Length and Width Deviation | ±3mm |

| Density | 1200kg/cubic meters | Thickness deviation | ±1mm |

| Water Immersion Rate | ≤0.5% | Impact Strength | ≥12MJ/m2 |

| Surface hardness | ≥65HD | Shore Hardness | ≥70d |

| Impact Strength | ≥ 20KJ/m2 | aging | 6-8 years |

| Flexural Strength | ≥30MPa | Temperature resistance | -20°C to 70°C, |

| Flexural Modulus | ≥2.0MPa |

FAQs

- Q: Are fiber brick pallets more durable than traditional pallets? A: Yes, fiber brick pallets offer enhanced durability and resistance to various elements, making them a reliable choice for brick transportation.

- Q: Can fiber brick pallets be recycled? A: yes, the fiber brick pallet can be recycle for reusing by theoretically, but in fact, Mostly, the fiber brick pallet is not recycled due to gathering cost.

- Q: Are fiber brick pallets cost-effective in the long run? A: yes, the fiber brick pallet is very cost-effective because of its long life, and it doesn’t need maintenance like wood pallet, make them more cost-effective.

- Q: How to Choose the right GMT brick pallets for your brick factory:A: Different raw materials are with different cost, because different materials has a little difference on their performance. So the GMT brick pallets price is based on its raw materials and different materials containing percentage. the key factors of GMT block pallet is their glass fiber content percentage, the more glass fiber content, its hardness is higher, performance is better, so it is very important to find an honest and professional pallet factory.

- Q: how to buy the fiber brick pallet from you?

A: (1) contact us to tell the basic requirement like size and quantity; (2) confirm how much block weight per pallet, if producing full solid block and curbstones, need to make sure the pallet is having enough thickness for not any bending; (3) Confirm our quotation and proforma invoice (4) make first payment for start producing the fiber brick pallets (5) showing produced pallet (6) making balance payment and arrange the shipment (7) sending the necessary shipment documents.

6. Q: is OEM service provided? do you need a wholesale for fiber brick pallet?

A: yes, we provide OEM service, we welcome the fiber brick pallet distributors, concrete block machine manufacturers in the world to cooperate with us, we will give necessary support to our Wholsalers;

considering all the advantages of fiber brick pallet like eco-friendly, long life, lightweight, cheap price, it is the first choice, other than the traditional brick pallets.

please feel free to contact us at whatsapp +86 1895499 3585 to give you a satisfactory buying experience.

Happy –

the fiber brick pallet is a new but high cost to performance pallet; it is eco friendly, helps the Earth to digest the useless leftovers; it is a good deed.